PRODUCTION

PRODUCTION OF SEALS

Quality seals are produced on the Seal Master CNC machine – “custom made”

Every seal for hydraulics and pneumatics, wiper, guiding type, or some other seals from 6 mm to 500mm can be made on our machine immediately.

This production process is without making special tool or mold, the machine can craft every seal dimension, standard or nonstandard, dimensions in inches…

With this procedure we make seals from all known modern materials for seals: NBR, H-PU, EPDM, H-NBR, PTFE-BRONZE, FPM and others.

Take a look at the MF Seals brochure for seals

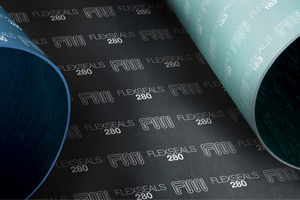

PRODUCTION OF NON ASBESTOS FLAT STATIC SEALS

Production of non asbestos flat seals

Production of precision static non asbestos flat seals in all possible geometric positions, in dimensions to 2500 x 1500mm. Seals have been produced on CNC plotter, that exclude the costs of tool and production time is very short. Maximum material is used with the “nesting” program (optimum position of the seals on the working board for maximum usage).

Materials that are used for production of the seals:

- Non asbestos plates made of aramid fibres , different elastomers and other materials

- Plates on the base of graphite with or without metal reinforcement for max t=550 C and p=500 bar

- Plate on the base of modified PTFE , t=1100C, p=200 bar

- Non asbestos term isolation and sealing plates on base of mineral fibres, t=1100C, p=2 bar

- Different types of elastomers ( rubber) like: NBR, H-NBR, FPM – VITON, SILICON, NEOPREN…

- Plates from PTFE – Teflon, POM, PE….

Take a look at our products

FOR MORE INFORMATIONS CONTACT US